We get a lot of questions about clutches, their operations, designs, and much, much more. But we’ve discovered there’s a need for a basic understanding of the language and terminology used in our sport. We hope to dispel just a little bit of the Black Magic surrounding stick shift racing to educate current and future customers.

Clutch Terminology

Air Gap – Measurable distance or “tolerance” between clutch discs and contact surfaces. (Example: When clutch is depressed, the amount of “air gap” between the disc and heat shield). Generally .040” – .070”

Bearing Retainer – The part the throwout bearing is attached to, moved by the clutch fork.

Bellhousing – Used to cover the clutch assembly. Contains the clutch/flywheel assembly in the event of failure, and connects the engine block to the transmission.

Base Pressure – (Also known as Static Pressure) Is the amount of clamping pressure applied through the coil springs or diaphragm. Adjustable units allow for “turns” of base to be added by turning each spring adjuster the same amount. This allows a clutch to be adjusted from a low amount of Base Pressure to a higher amount. (Example: 0 Turns may be 200 lbs, 8 Turns might be 1200 lbs allowing 1000 lbs of adjustment)

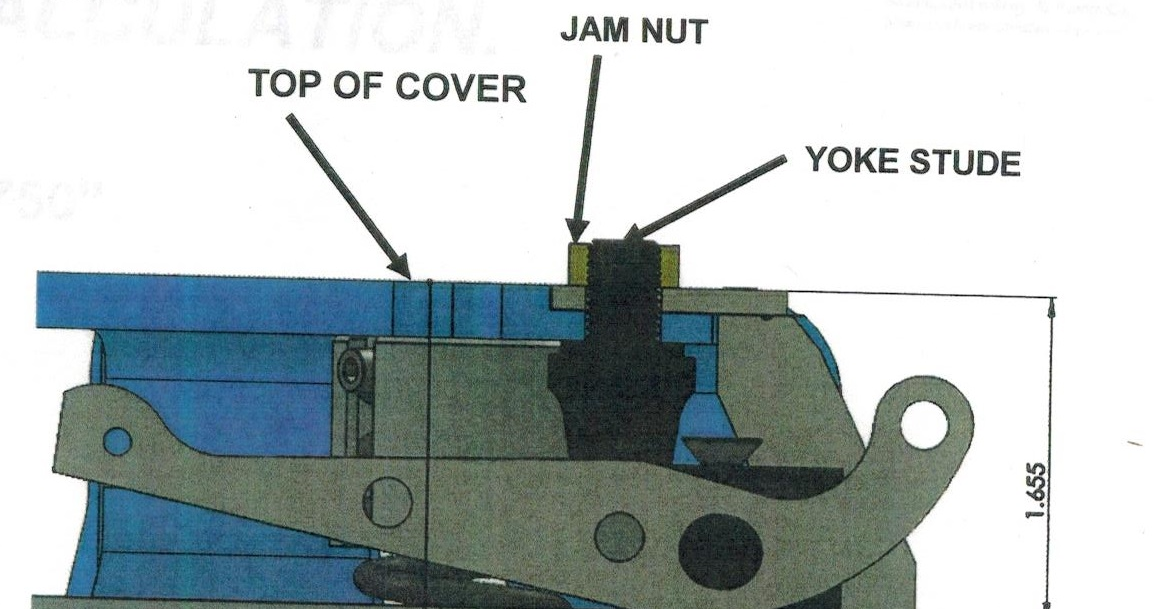

Billet “Pro” Clutch – A clutch type generally used in advanced tuning/performance applications. The cover and pressure plate are constructed from billet material, most often Aluminum, Titanium or High Grade Steel. Levers are placed evenly around the cover top and do not extend outward past the external diameter of the cover. This type of clutch most commonly has adjusters located between the cover assembly and flywheel to adjust for the wear of friction discs and related parts.

Candle Stick – Mounts inside the bellhousing and extends from the face of the transmission for the bearing retainer to be guided by. Generally used in “Pro” style applications to assure exact tolerance and motion, while also housing optional clutch/input shaft speed sensors to be mounted.

Clutch Assisted / Clutchless Transmission –

– Clutch Assisted – The transmission is designed for the driver to disengage the clutch pressure “use the clutch” when shifting gears.

– Clutchless – The transmission is designed for the driver to shift without using the clutch in gear changes.

Clutch Cover – The cover is the top piece of the clutch that holds either the diaphragm or coils springs captive between itself and the pressure ring. On adjustable base pressure clutches, this is where the adjusters are found around it’s circumference.

Clutch Fork – Arm that extends outside of the bellhousing that is connected to the clutch pedal by linkage. It controls the movement of the throwout bearing and thus the actuation of the clutch itself.

Clutch Lever – Lever designed to engage and disengage the clutch by causing the pressure plate to travel towards and away from the clutch cover when the clutch is actuated. Usually 3, or 6 levers are used, however multistage lockup clutches used in Top Fuel / Funny Car “Nitro” may use more.

Counter Weight – Weight applied to the external side (outside the cover, away from the throwout bearing), to apply additional applied pressure or clamp load. As the rpm of the clutch increases, the more pressure the counter weight applies. Additionally, the more counter weight used, the more available pressure. This also allows for decreased pressure after a gear change, allowing clutch slippage to control wheel speed.

Coil Sping – A spring of coil designed used to apply pressure to the clutch pack. Can be adjustable or fixed in pressure application. Most clutches use 6, 9 or 12 springs spaced out evenly throughout the cover.

Diaphragm – Type of clutch spring that is concave and circular in design, used as a spring to apply constant pressure to the clutch pack/pressure ring.

Disc Carrier – The steel blank that the friction materials are bonded/sintered/riveted or attached in another fashion.

Free Play – Amount of movement in the clutch pedal / distance of throwout bearing from clutch levers/diaphragm before actuation.

Friction Disc – The disc is the part which various types of friction materials may be used to create “Friction Coefficient”. The input shaft spline is found in the hub of the friction disc.

Heat Shield – The heat shield is the insert or inserts attached to the pressure plate or flywheel that the friction discs run against. These are generally either riveted on or bolted on with the bolt tips ground down for a smooth finish. They may also be segmented (multiple “Pads”)

Hub – The splined part of a disc, generally riveted onto the disc carrier.

Line Lock – Device used to hold applied pressure to the front brakes only. Used to stage to prevent the car from rolling or “creeping” through the staging beams.

Long Style Clutch – This type of clutch is known for the levers being “long” extending outwards past/through the cover assembly, allowing for counter weight to be added at the outside point of the lever. Although they do not have to have counter weight option/location. Most often utilize 6 or 9 coil springs and can have adjustable base/static pressure.

Pressure Plate – This is the lower part of the clutch cover assembly that has a heat shield attached to it. It is where the levers on a “Long Style / Borg and Beck / Pro Billet” style assembly apply pressure and are made to pivot on. It also applies the base or spring pressure. It is where the pressure is applied downward to the heat shields and friction disc.

Throwout Bearing – Bearing that travels to actuate (engage/disengage) the clutch assembly. Made of a ball bearing or needle bearing design. Rides on bearing retainer that attaches to the clutch fork.

Transmission Sliders – Mounts bolted/attached to the transmission that allow the transmission to slid backwards away from the bellhousing when removing or servicing parts. Generally elongated rails attached to the transmission that sit in tubular cradles attached to the vehicle.

Transmission Sliders (Internal) – The part in which the shifter fork is attached for each gear that allows the slider to move into an engagement position with the gear set itself on the main shaft.

Two-Step – A limiting switch used to control the rpm of the engine during launch.

**”Ramping it in” – A term used to refer to when you allow the engine rpm to begin increasing slightly just before or as the clutch is released.

Wheel Speed – RPM rate at which the wheels/tires spin. Usually monitored through a driveshaft rpm sensor.

TYPES OF FRICTION MATERIALS

Sintered Iron – Most commonly used in drag racing. It is utilized for it’s aggressive friction coefficient, consistency and ability to be controlled through applied pressure with precise repeatability and predictability.

Kevlar – A high-durability material more resistant to hard use. Engagement is similar to organic, but may glaze slightly in stop-and-go traffic, resulting in slippage until worn clean when used hard again. Higher temp range in general, but can be ruined from overheating – will not return to original characteristics if “cooked”. Has a break-in period of 500-1000 miles during which slippage may occur. Care must be taken during this period not to overheat from excessive slipping. Material is uniform yellow/green and may look slightly fuzzy when new.

Organic – Metal-fiber woven into “organic” (actually CF aramid with other materials), original- equipment style. Known for smooth engagement, long life, broad operating temperature, minimal-to-no break in period. Will take hard use, somewhat intolerant of repeated abuse (will overheat). Will return to almost full operational condition if overheated. Material is dark brown or black with visible metal fibers.

Carbon / Ceramic – Very high temperature materials, usually only found on multi-puck disks. Will accommodate 500hp+ Engagement is more abrupt. Will wear flywheel surface faster, especially in traffic situations. Carbon is slightly more durable and flywheel-friendly, ceramic has a higher temp range. Multi-puck design may result in slight shuddering or “stepped” engagement when used in traffic situations, although many users report completely acceptable operation. Material is any of several light hues – gray, pink, brown.

Cerametalic / Bronze – Very aggressive, often used on floaters and heat shields in conjunction to sintered iron discs to increase friction coefficient. Gains friction coefficient with additional heat. Used in extreme street/road race applications in puck form generally. Engagement is generally more abrupt, yet not on/off.