It’s time to step your game up

Our traditional Long Style clutch units are commonly used in heads-up drag racing, bracket racing, grudge racing, salt flat land speed, standing mile, truck & tractor pull, pro street, and drag-n-drive racing.

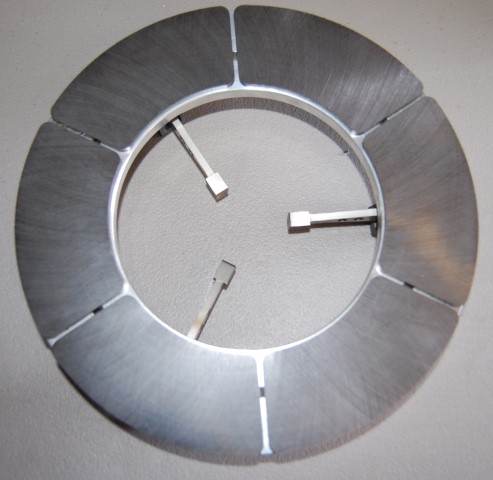

Our stamped steel units are tried and true warriors. We designed them to handle a wide range of vehicle types and racing styles. They’re more affordable than some of our other options, but still have excellent performance. Many, many Black Magic customers have won with this clutch.

Stamped Steel Long Style Specifications And Features

Our traditional Long Style clutch units are commonly used in heads-up drag racing, bracket racing, grudge racing, salt flat land speed, standing mile, truck & tractor pull, as well as Pro Street and Drag Week type street strip.

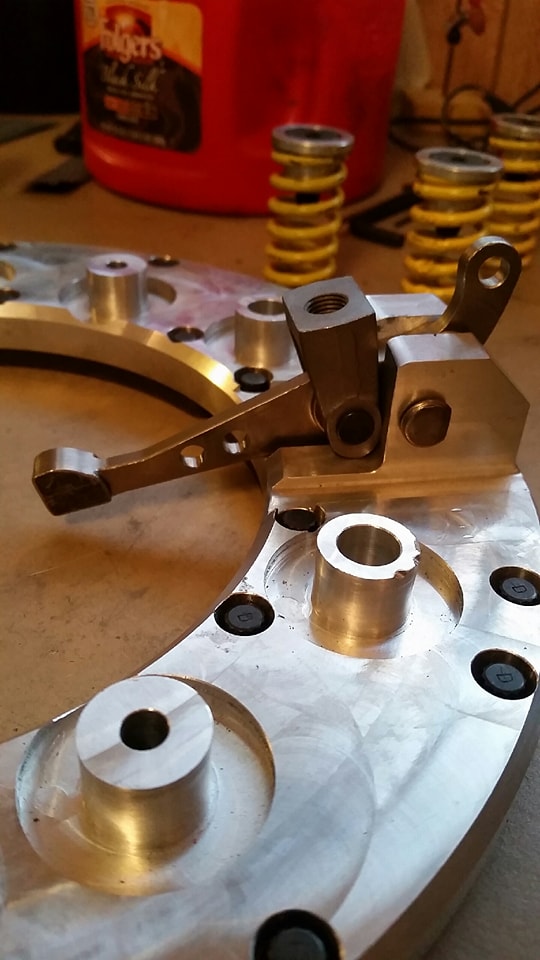

Our clutch units all have available applied pressure information gained through in-house Clutch Dyno testing and developments. This allows us to know exactly how much pressure is applied at all times through your given rpm range. Adjustable or “Slipper” style clutches are designed to apply less pressure at lower rpm, and gain additional pressure as more rpm is achieved. Additionally, by adding or removing Counter Weight (Nuts/Bolts/Washers), measured in grams we are able to change the rate of applied pressure applied over rpm. The static Base Pressure is adjusted by turning each base adjuster (Generally 6 springs), to increase or decrease pressure as desired.

As an example using the base and counter weight charts above and the car information below:

Car: 3200 lbs, 875 hp, 8800 shift rpm, 5000 launch rpm, 28×10.5 Tire, 3.05 First Gear, 5.00 Rear Gear

Launch RPM: 5000

Base: 3 Turns = 572 lbs

CW: 30g -23.382 lbs per gram (23.382 X 30) = 701.46 LBS

Base and CW together = 1273.46 lbs Total Pressure

If we target a Lock-Up Rpm of 7400 rpm:

Base: 3 Turns = 572

CW: 30g – 52.61 lbs per gram (52.61 X 30) = 1578.30 Lbs

Base and CW together = 2150.30 Total Pressure

With this you can see how you would leave at one pressure (1273.46) allowing for slippage, while achieving an additional 876.84 lbs of pressure to lockup at a desired rpm. By adjusting the Base/CW balance and totals, you can effectively determine exactly when you want the clutch to lock up. While seat of the pants tuning you can definitely make significant gains in performance, however when logging engine rpm, driveshaft rpm and clutch rpm we can specifically determine the exact point of lockup. Once you know the amount of pressure required to lock the clutch 1 to 1 with engine rpm, you can easily calculate and adjust the total pressure desired at a given rpm.

Our Stamped Steel Style Long Style units are available for all applications using larger tooth ring gear counts. (GM/Chevy 168t and larger, Ford 164t-176t-184t, Mopar 143t, Pontiac 166t) – Addition applications available upon request.